Rodrigo Augusto Lippi

DLG Automação LTDA

rodrigoalippi@dlg.com.br

ABSTRACT

DATA-LOGGER APPLIED TO COLD STORAGE

Proposed a low cost solution for a data acquisition system applied to frigorific chambers, to meet the need for monitoring the temperature of these environments that influence directly the quality of the stored products.

Key words: Data-Logger, Modbus/RTU Master, industrial networks, cold chamber, frigorific.

INTRODUCTION

The refrigeration process is pretty old: history tells that the Chinese were the first to use ice to cool beer and that the Egyptians kept jars full of water on the outside of their houses during the night so that the dry desert wind cooled it through the humidity evaporation.

Also some culinary books from the ancient Romans referred to the use of snow in some of their dishes to preserve them.

In 1863 the microscope was invented and the scientists discovered the bacteria, when it was verified that when the food temperature was reduced, the decomposition of food by the growth of the number of bacteria was delayed.

In 1890, there was a very mild Winter in Europe, which caused a shortage of ice from the glaciers on the following Summer, which otherwise allowed the upper classes to store their food for consumption.

The shortage of ice gave start to the Search for Cold, when we began to foresee the birth of the Market of Cold or the industrialization to that purpose.

But only on 1913, there happened something more concrete with the outcome of the first portable refrigerators and on 1918 the electric refrigerators. And from 1926 on there was the conception of the hermetic compressor. The biggest concern then and still prevails nowadays was to decrease the vital functions of the bacteria responsible for the food alterations

Frigorific chambers are compartments refrigerated, closed, thermally insulated, inside which are kept thermo-hygrometric conditions, i.e., adequate temperature and humidity for the preservation of edible products. The maintenance of the thermo-hygrometric conditions is provided by refrigeration unit, eventually integrated by heat and humidification systems. Each frigorific chamber must be designed for a given purpose, whose thermal load to be supported by the frigorific equipment and the period of time required by the process should be criteriously calculated.

The frigorific chambers with temperature around 0ºC and high relative humidity are used in the preservation of fresh food for short periods of time. The low temperature chambers, characterized by a high thermal insulation, sustain the temperature required by long-term preservation of frozen food. The chamber of medium-high controlled temperature are characterized by absolute tightness and are equipped to produce artificial atmospheres that prolong the preservation of some green products.

The chambers that control the ripening of green products have high-medium cooling temperature. They have a structure similar to those chambers of controlled atmosphere whose thermo-hygrometric conditions vary in the open air in function of pre-established cycles..

This article will focus on monitoring the atmosphere through a system of data acquisition, on frigorific chambers with temperature around 0ºC and relative humidity used for meat storage, dairy products etc.

DATA ACQUISITON SYSTEM

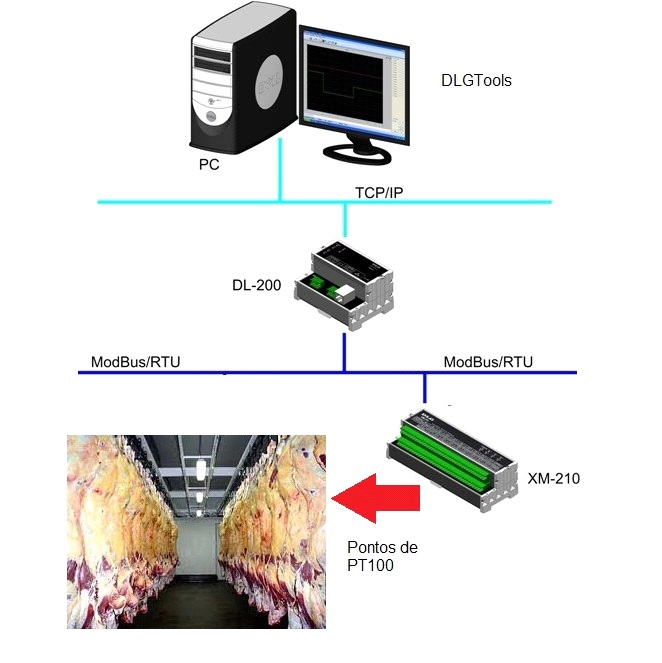

The data acquisition system is a solution provided by DLG Automação Industrial is constituted by three products. The first product is the XM-210 (Modbus Universal Remote), the second product is a DL-200 (Data-Logger) and the third product is the DLGTools software.

The Modbus Remote Universal XN-210 has 16 channels independently configurable to measure the following greatnesses: current (mA), voltage (V and mV), frequency (Hz), thermo-couple sensors (ºC) and PT100 (ºC). They used the first five channels configured for PT100 sensors.

The PT100 sensors were distributed in strategic points inside the frigorific chamber to monitor if the temperature remains homogenous within the chamber.

The Modbus Universal Remote also has two independent communication doors that use the Modbus/RTU slave protocol applied to the communication networks whose physical means is the RS-485.

The DL-200 Data-Logger main feature is the fact of being a Modbus/TRU Master. The DL-200 has a communication door for RS0485 networks and an Ethernet door (Modbus/TCP) for equipment configuration and monitoring and data download.

The acquired data are Modbus/RTU registers that characterize the Modbus /RTU slaves connected to the RS-485 network. The data are stored in a memory card MicroSD type with capacity up to 2GB.

The DLGTools software is a gratuitous tool responsible for the configuration of all Modbus/RTU and Modbus/TCP products manufactured by DLG Automação.The software can be downloaded directly on the company site.

Figure 1 illustrates the network topology in the data acquisition system.

Figura 1 – Topologia de rede

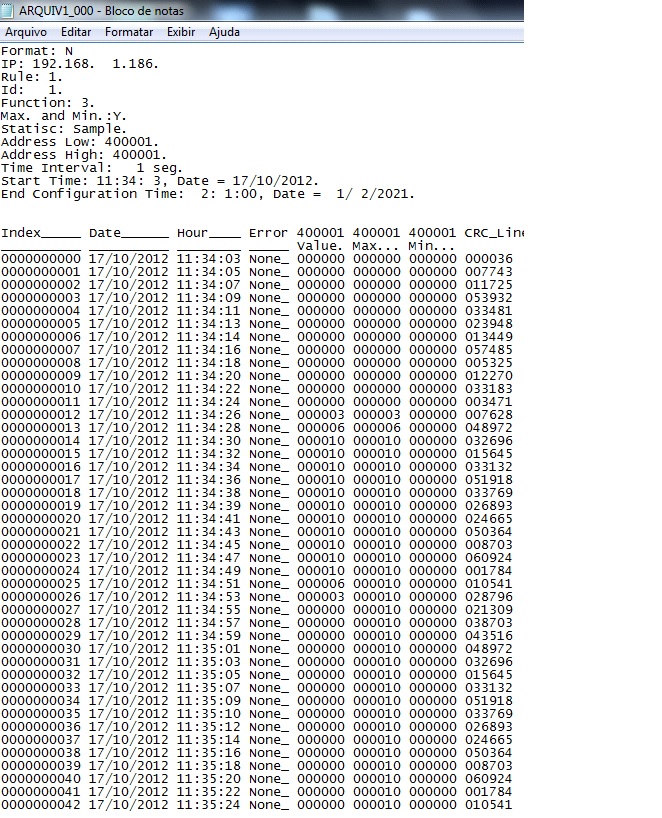

Figure 2 illustrates a small part of the file generated by DL-200 in text format. An XM-210 Modbus register corresponding to the first analog channel with PT100 sensor was then acquired. The temperature stays around 0ºC with maximum and minimum variation of 1ºC and resolution of 0,1ºC.

Figure 2 – Report generated by Data-Logger DL200

Figure 3 illustrates a data Trend presented by the DLGTools from the same Modbus register referring to the PT100 reading.

Figure 3 – Report generated by Data-Logger DL200

CONCLUSION

It is evident how important is for consumers the quality control employed by the food industries in their storage frigorific chambers.

The temperature control in these facilities is essential to avoid alterations in the food produced by microbial, chemical and physical agents

A data acquisition system is a powerful tool that helps monitor and analyze data.

The data acquisition system using the Data-Logger DL-200 combined with other devices is a low-cost solution with satisfactory results.

ACKNOWLEDGMENTS

The author thanks Control and Instrumentation magazine for publicizing this article

BIBLIOGRAPHY

11/2/2014 DATA-LOGGER APLICADO EM CÂMARAS FRIGORÍFICO | DLG Automação

http://www.dlg.com.br/artigo_destaque?artigo=60 7/7

[1] XM210,User Manual. Available on:

[2} DL200,User Manual. Available on:

ABOUT THE AUTHOR

Rodrigo Augusto Lippi

Research and Development Engineer

DLG Equipamentos LTDA

Rua José Batista Soares, 53 – CEP 14176 – Sertãozinho – SP

Telephone: (55)(16) 3513-7400

Email: rodrigoalippi@dlg.com.br

To download this article click here

[3] Ambiente Gelado. Available on