Ronaldo Tomazeli Duarte

Engenheiro de Pesquisa e Desenvolvimento, DLG Automação Industrial

ronaldo@dlg.com.br

The efforts to standardize industrial neworks presented excellent results, practically eliminating proprietary protocols, while offering to final users tranquility to enable equipment from different makers to be inter-connected in network with guaranteed interoperability. For the manufacturers, standardization avoided huge integration costs, previously found at most proprietary protocols.

Even with the mentioned standardization, the diversity of the industrial applications hinders the existence of only one network specification capable of meeting all requirements for installation, safety, functionality and performance. Hence, multiple network standards are found in industry, like, for example, Profibus, Modbus, HART, Foundation Fieldbus, among others. Each standard offers one feature that makes it more suitable for a specific application.

Faced with this situation, different networks are commonly used in the same plant, and very often the transference of information is needed between the several equipment connected in different (and compatible networks).

To meet this necessity equipment like gateways, bridges or converters are used. A gateway integrates two or more networks, and it must capable of transforming the information format conveniently.

LMP-100 is a Profibus DP / Modbus RTU gateway with resources that allow connecting both networks. In other words, the LMP-100 assumes simultaneously the roles of slave in the Profibus DP network and master in the Modbus RTU network, permitting Modbus slaves, like remote, indicators, etc., to be controlled by Profibus, PLCs masters.

Figura - LMP-100

LMP-100 is entirely configurable by the network through the parameterization foreseen in the Profibus status device. All parameters that control the LMP-100 operation are described in the GSD file that accompanies the equipment. Therefore, there is no need for a specific configuration software, since the parameters are transferred by the Profibus master, while the configuration management of the equipment is reduced, as the LMP-100 is simply connected physically to the network as soon as the master detects the presence of the equipment.

To map the data between the Profibus and Modbus networks, the LMP-100 defines the Modbus rule concept, which can be classified in input rules and output rules. Input rules specify the variables that must be read from a Modbus slave. The variables read from Modbus slaves are processed and made available to the Profibus master through the Profibus DP data exchange cyclical mechanism. Output rules specify which variables from the Modbus slaves must be written. The values to be written are also sent to the Profibus master through the data exchange cyclical mechanism.

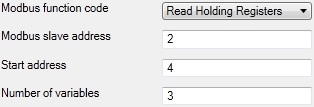

Figura – Modbus rule configuration

The rule presented on figure 1 indicates to the LMP-100 the need for reading the variable on the Modbus slave with address 2. According to the nomenclature frequently used for Modbus variable addresses, such rule tells that the LMP-100 will read the 40004, 40005 e 40006 variables and will make these data available on the Profibus network through the exchange of

cyclical data.

The output rules configuration is made the same way. However, in the output rules the

LMP-100 writes on the Modbus slaves, and to allow the equipment to be flexible to meet the many scenarios the mechanism that controls the exact writing moment is then configured. For example, the LMP-100 allows the variable to be d automatically on the slave, when it detects a change in the value sent by the Profibus master. Also it is possible to configure the mechanism in a way that the variable is written on the Modbus slave only if necessary, after user definition.

An important differentiation in the equipment is the amount of diagnostics information enabled on the Profibus network. Any parameterization or operation failure in the Modbus network is indicated to the Profibus master. As the equipment is focused on flexibility, there are two ways of collecting diagnostics, allowing the user to choose the best to suit his system. One of them is the native diagnostics mechanism extended by the Profibus DP, and the other is sending the data cyclically.

The LMP-100 can process a total of 28 Modbus rules, which permits that a large quantity of variables is transferred by equipment.

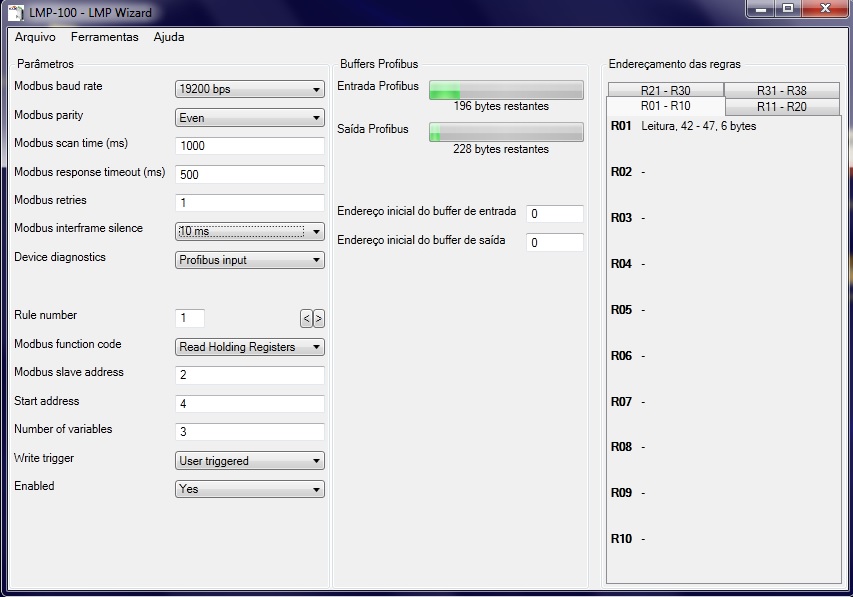

The LMP-100 configuration is simple, that only requires indicating which Modbus variables must be read or written. As a support to the configuration, the LMP-100 is accompanied by the LMP Wizard tool. The LMP Wizard is a Windows application included freely. The application interface is shown on figure 2.

Figure - LMP Wizard

The LMP Wizard offers the user the LMP-100 configuration parameters and by adjusting them the tool builds the maps of the several Modbus variables, indicating their position in the memory areas cyclically transferred on the Modbus network.

Besides mapping, the tool analyzes the consistency of the configuration, indicating errors in addressing, quantity of mapped variables, etc.

The LMP Wizard makes PDF reports to consolidate the LMP-100 configuration. The reports can also be used on the application project and as documentation to configure each LMP-100 installed in the plant.

The conclusion is that the LMP-100 is an easily configurable and efficient gateway, extremely flexible and designed to meet the most different applications. Combined with the LMP Wizard it became a very interesting option for applications involving the exchange of data between Modbus and Profibus networks.

Click here to download this article